In the Know | Wood Table Tops. Updated

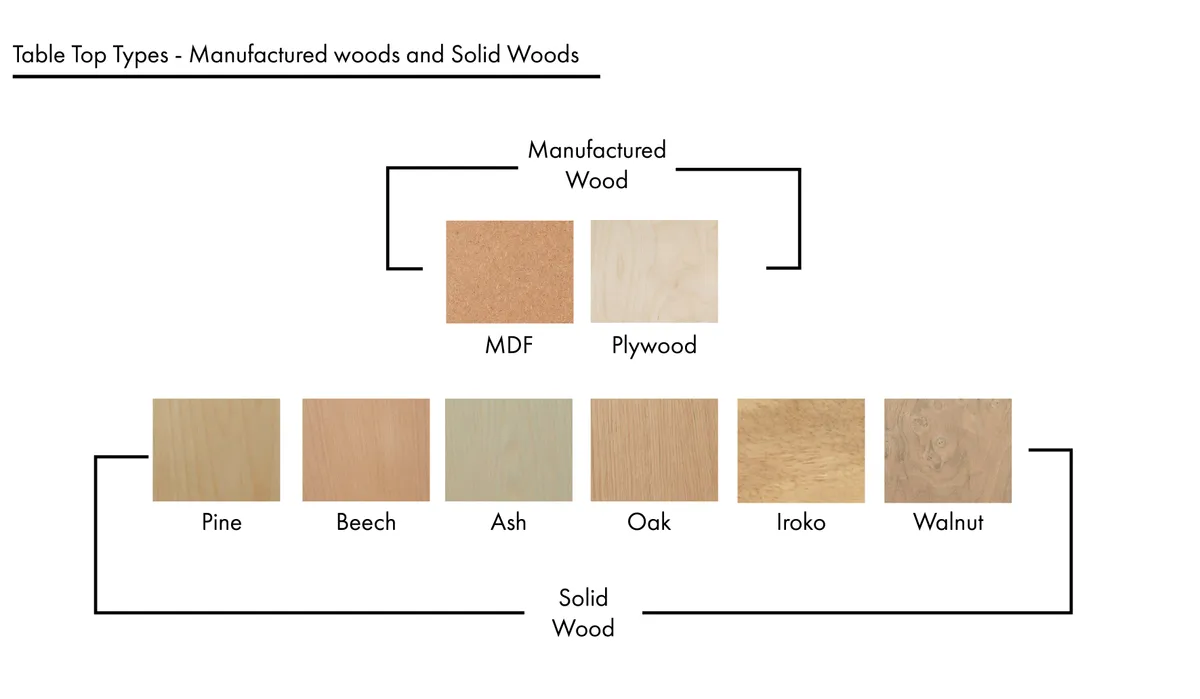

Wood: the most popular choice for table tops

Whether you’re sourcing a counter top, bar top, or dining table, this versatile material is strong, practical, and aesthetically pleasing. You can choose from numerous types of wood – such as beech, ash, oak, and walnut – each with unique qualities and characteristics. Wood can also be customised with different stains, colours, shapes, surface effects, and edging to create unique pieces to complement your interior.

Step 1: Choosing your Table Top Wood

Table Top Wood for interior use

Beech

A hardwood with a faint, fine grain and texture. Beech is a cost-effective option and is the most popular choice for furniture frames and table tops where a grain is not desired, such as painted dining tables. All seasoned Beech is FSC and sourced from Europe.

Ash

A hardwood that is lighter in colour and cheaper than oak. Ash wood bends nicely and is commonly used for bespoke tables and bentwood furniture. This wood is sourced from Europe. Ash is cheaper than Oak and a great alternative due to the grain detail.

Oak

A hardwood that is available in two main types: European and Character oak. Oak is popular because of its graining. It is more expensive than beech and ash, so might be used for a centrepiece oak table top or solid oak dining table. Character oak features knots and open grains and is one of our most popular wood choices for hospitality. Both oak types are sourced from Europe; British oak is available but is more expensive.

Walnut

A hardwood that is desirable for its grain and dark colour but is also very expensive. For a cost-effective alternative, you could use ash wood that is stained to walnut, which will show similar graining.

Recycled and reclaimed wood

These are sourced in a variety of ways – from used scaffolding boards, floorboards and off-cuts from larger scale woodworks to upcycling existing pieces of wood. These table tops can be stained, painted, and include mix-and-match woods to create a unique look. This is also an eco-conscious option, as it utilises timber that would otherwise contribute to landfill. recycled table tops >>

Our in-house design team can assist you with bespoke painted designs, or you can keep it simple for a close alternative to standard wooden table tops.

Wood for exterior use

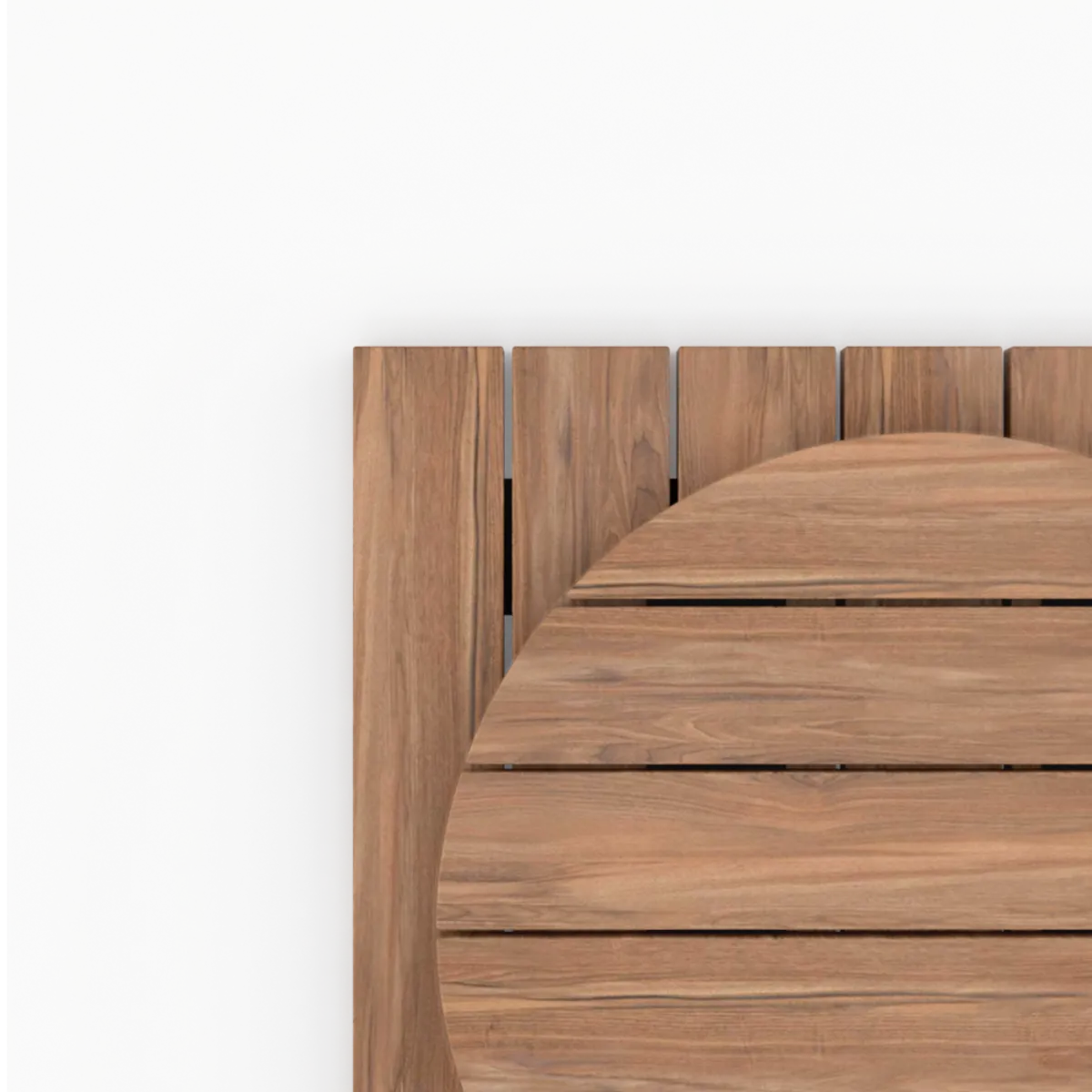

Robinia and Iroko

Both Robinia and Iroko are hardwoods that are suitable for outdoor use. Often slatted with gaps to allow water drainage, or with holes (moneybox style), these wood types are the most commonly used options for outdoor tables.

Wooden tops made from planks of wood

This is a common production method and they can be made in different widths which can be assembled in patterns to create custom designs. Thinner planks are generally more stable than thicker planks.

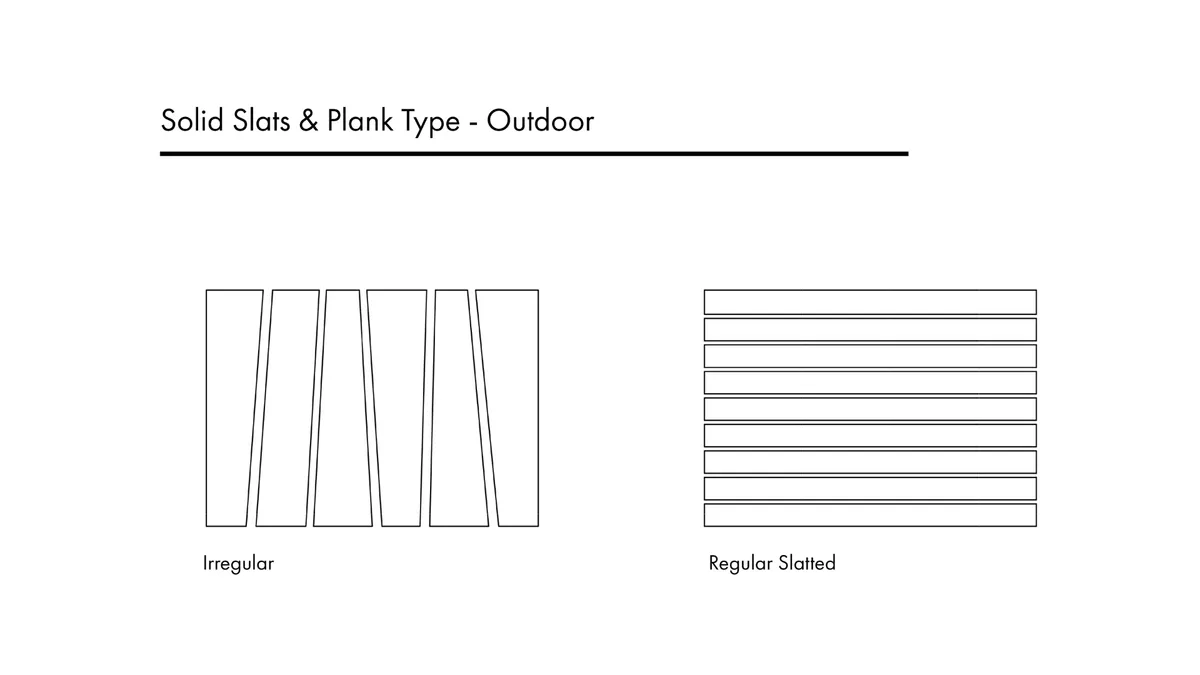

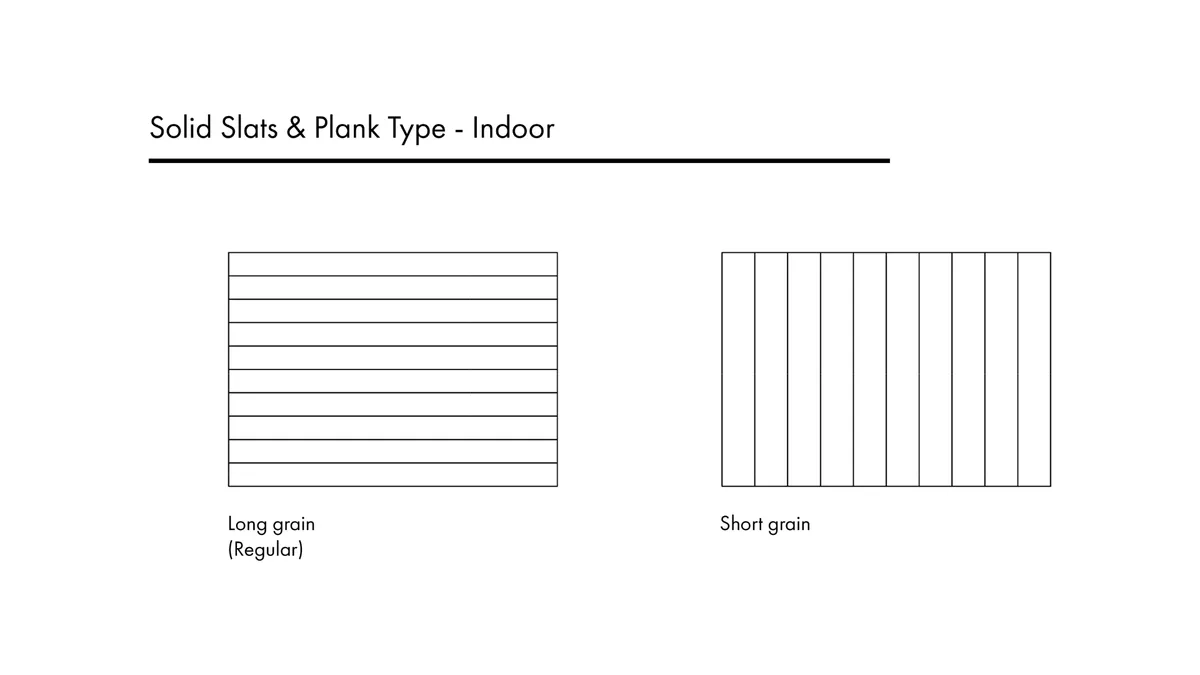

Slatting types

The main differences are whether the construction is long grain or short grain, and whether it is regular or irregular. If planks run along the long edge of a table top, they’re known as ‘long grain’. If they run across the shorter edge they’re known as ‘short grain’. Evenly spaced and sized planks are ‘regular’, whereas a more haphazard-looking design is known as ‘irregular’.

The planks will warp if they’re not reinforced and the standard reinforcement is called a batten. These are strips of wood that are screwed to the underside of the table in the opposite direction to the planks.

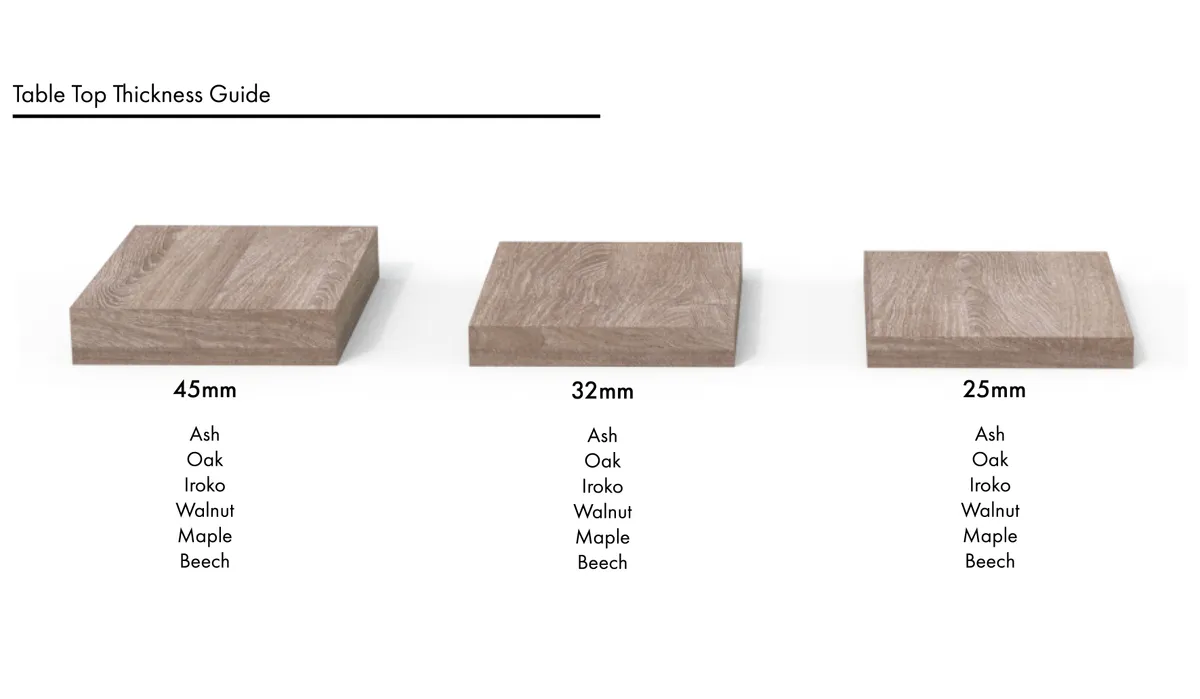

Choosing the right thickness

The thickness of your wood table tops will generally be determined by the type of wood you choose, as the planks are supplied in standard measurements. You will usually have the options of 25mm, 32mm or 45mm if you’re thinking of a solid wood table. The exception to this is Character oak, which is a particularly knotty wood that is less rigid in the thinner measurement. If you’re thinking of a veneer table finish, you’ll be looking at thicknesses from 18mm to 38mm.

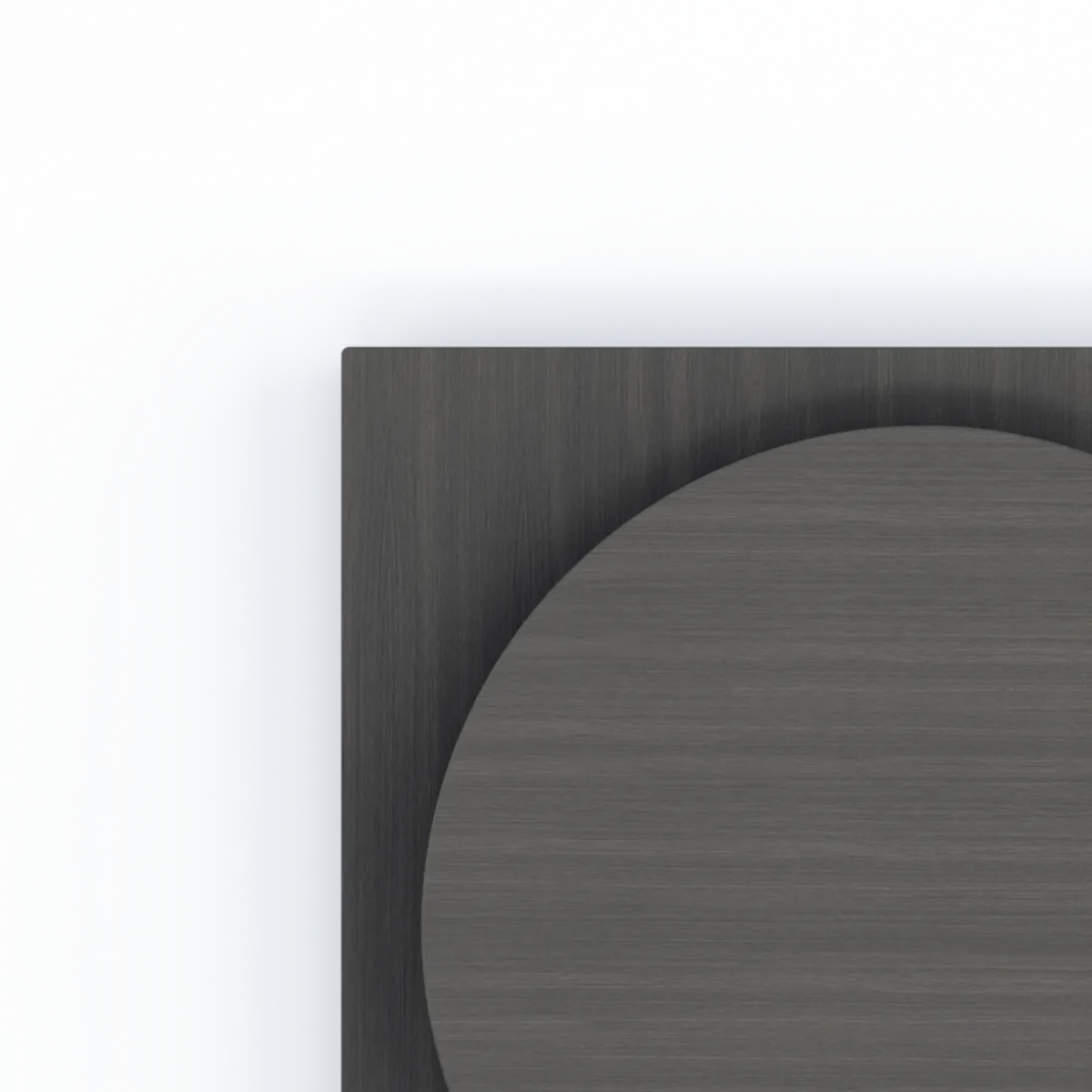

Step 2: Solid, Laminate or Veneer?

Solid wood

Exactly as it sounds, the solid wood construction is ideal for a stunning centrepiece table. Solid wood is a good choice for high-usage furniture, as it is easy to maintain and to repair dents and scratches. It’s an expensive option but you’ll recoup the costs over time due to its longevity.

Laminate

A manufactured core is covered in a laminate sheet, that is extremely hard-wearing and heat-resistant, so perfectly suited to hospitality settings.

Veneer

A manufactured core is covered with a thin layer of wood veneer. This extends around the edges to give the impression of solid wood, although it is more cost-effective. It is low maintenance but looks good, so would be well suited to bar tables or high-usage dining table tops.

Step 3: Choosing your Wood Finish

Stains, Oils and Lacquers

Your wooden table top is a blank canvas, waiting for you to get creative and choose a finish to enhance the natural grain, or paint over it and create an entirely new look.

A stain is painted directly on top of the timber. It will often be used to mimic other wood types and requires a clear lacquer to be painted on top, in order to prevent or slow down fading over time.

Oil permeates the timber, protecting the surface from damage. It is used to preserve the natural look and feel of the wood underneath and it requires regular reapplication to maintain the effects of the oil and the properties of the wood.

Lacquer forms a solid, even layer to the top of the wooden surface. There are a variety of lacquers, ranging from clear to RAL colours, and these come in sheens that range from very glossy to very matte.

Standard sheen ranges:

• 10% matt

• 20% satin

• 40% gloss

• 60% high gloss

The higher the sheen, the stronger the lacquer and therefore the better protected the wood will be. However, scratches will be much more visible in a high-gloss finish. Lacquer can be applied on top of a stain to protect it, but it can’t be applied on top of an oil, as the oil will reject the shiny lacquer paint.

Step 4: Choosing a Wood Effect

Wood surface effects

Now that you’ve chosen your wood type, stain, and lacquer, you can also decide if you want to add a surface effect to create a truly unique piece for your venue.

Wooden surface effects can create a lot of character and bolster your design brief. For example, charred or wire-brushed finishes are popular for industrial and farmhouse-style venues. Meanwhile, limed surfaces are popular for clean minimalist interiors, as they add a whitewashed matt touch to table tops.

Bandsawn

Bandsawing timber gives the wood an uneven surface texture and dramatic effect. This technique is popular for rustic-style restaurants and bars.

Sandblasted

This technique is a bit like sandpapering with a jet stream. Sandblasting gives the wood surface a deep texture and it will remove the top layer of the timber, revealing extra layers of colour underneath.

Wire-brushed

This effect gives the timber a subtle texture and enhances the depth of the grain. You should only oil finish a wire-brushed table top because lacquer will diminish the texture.

Fumed

This technique involves exposing the timber to ammonia, which results in a lightly charred effect.

Charred

Charring occurs when the wood is exposed to heat, usually by using a blow torch. The surface is burned just enough to bring out the different textures within the natural grain.

Limed

This effect is created using a liming wax, which results in the wood looking whitewashed.

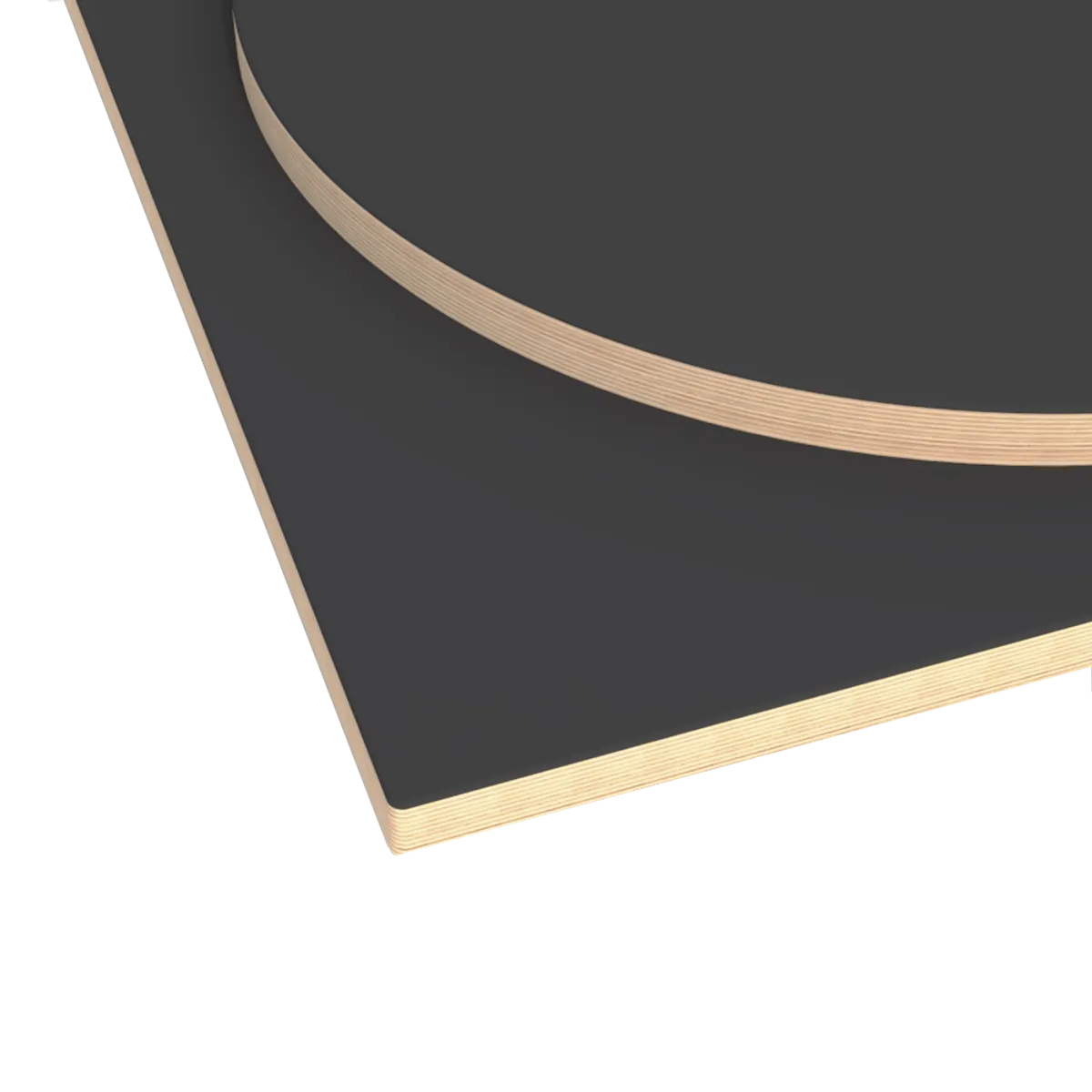

Step 5: Choosing a Wood Edge

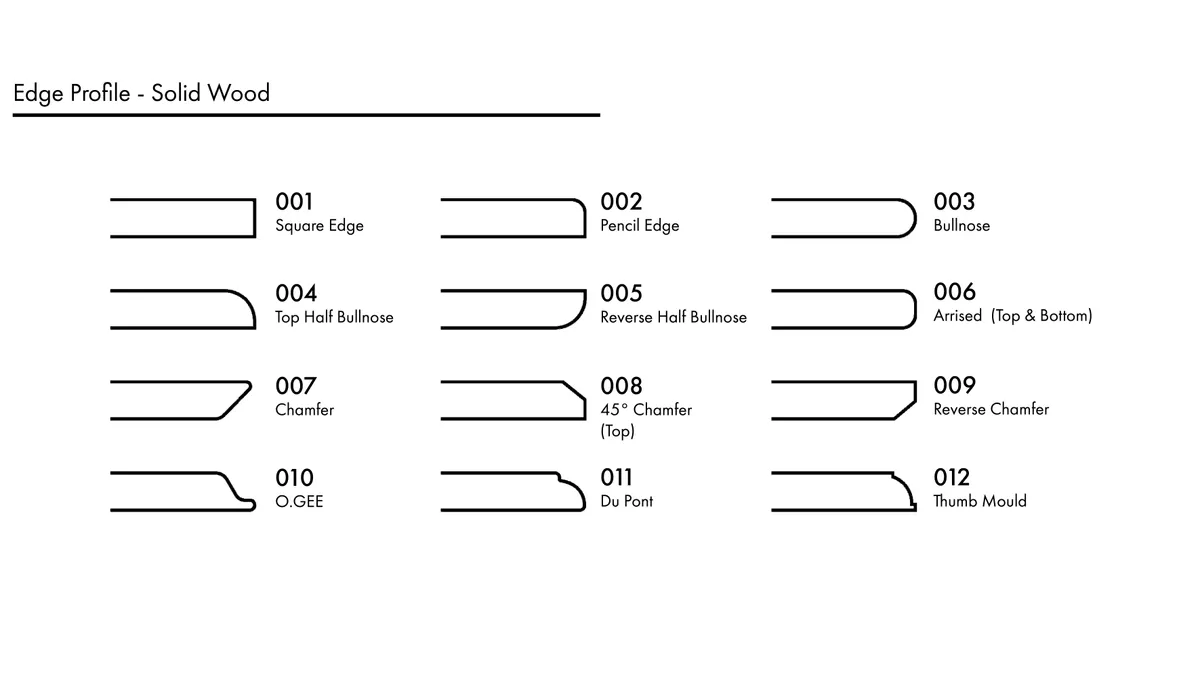

Edge Profiles and Edging

This is the final step in your table top specification and adds character to everything from bar tops to dining tables. If you’ve chosen solid wood, you can opt to leave the edges bare and choose a profile such as straight, chamfered or bullnose. Our design team can advise which might be most suitable for different applications, for example, an oak bar table, or a communal dining table.

The other option is to add an edge. The two most popular edges for wooden table tops are a solid wood border (recommended for recycled options where the timber is not always straight-cut and requires a border) or a metal edge.

Solid Wood Border Edge

This striking design feature works particularly well with smaller table tops, or as a feature on wooden bars. It is almost like framing a picture and turns your piece of furniture into a work of art. As with all options, check the lead time for your chosen design, as some finishes and techniques will take longer to craft.

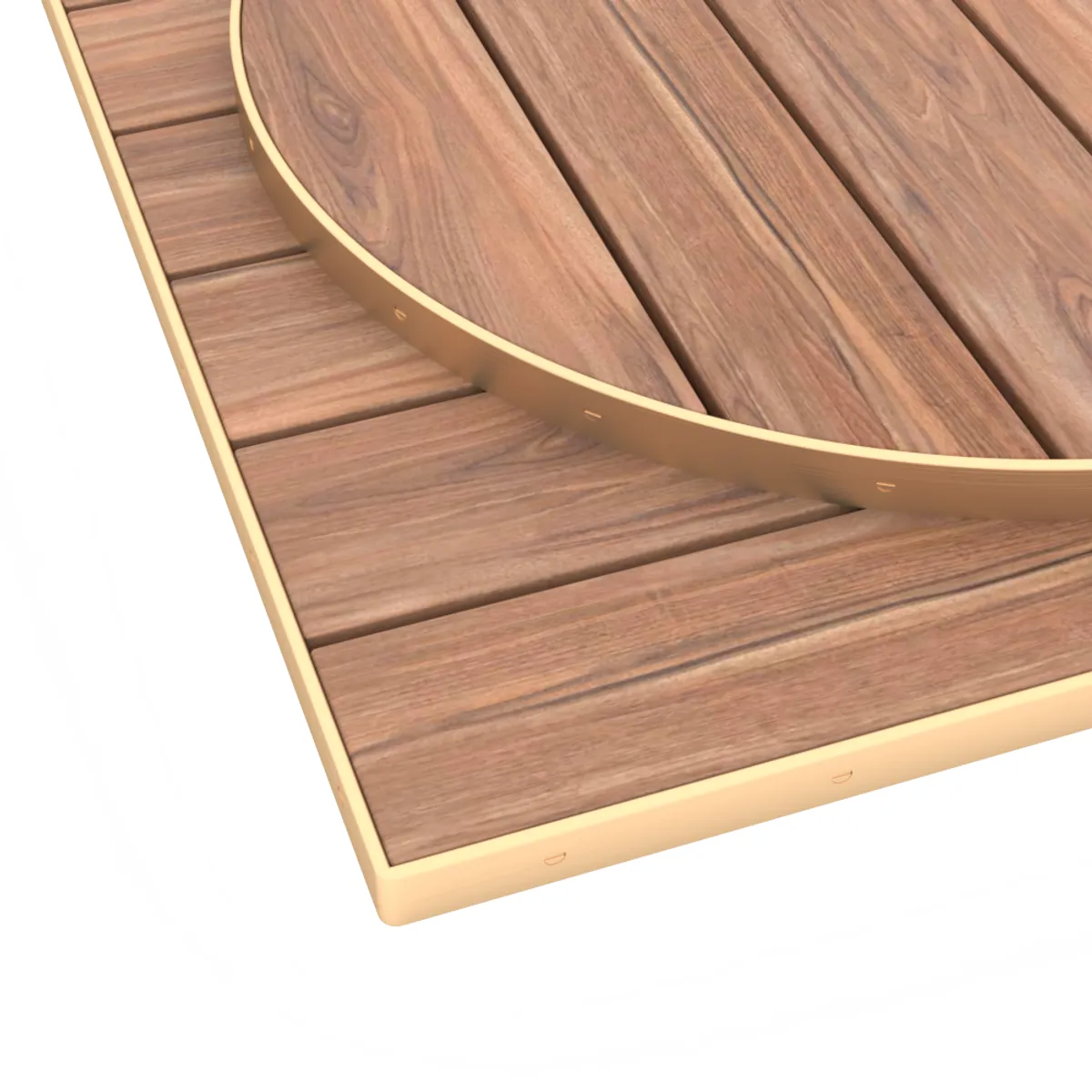

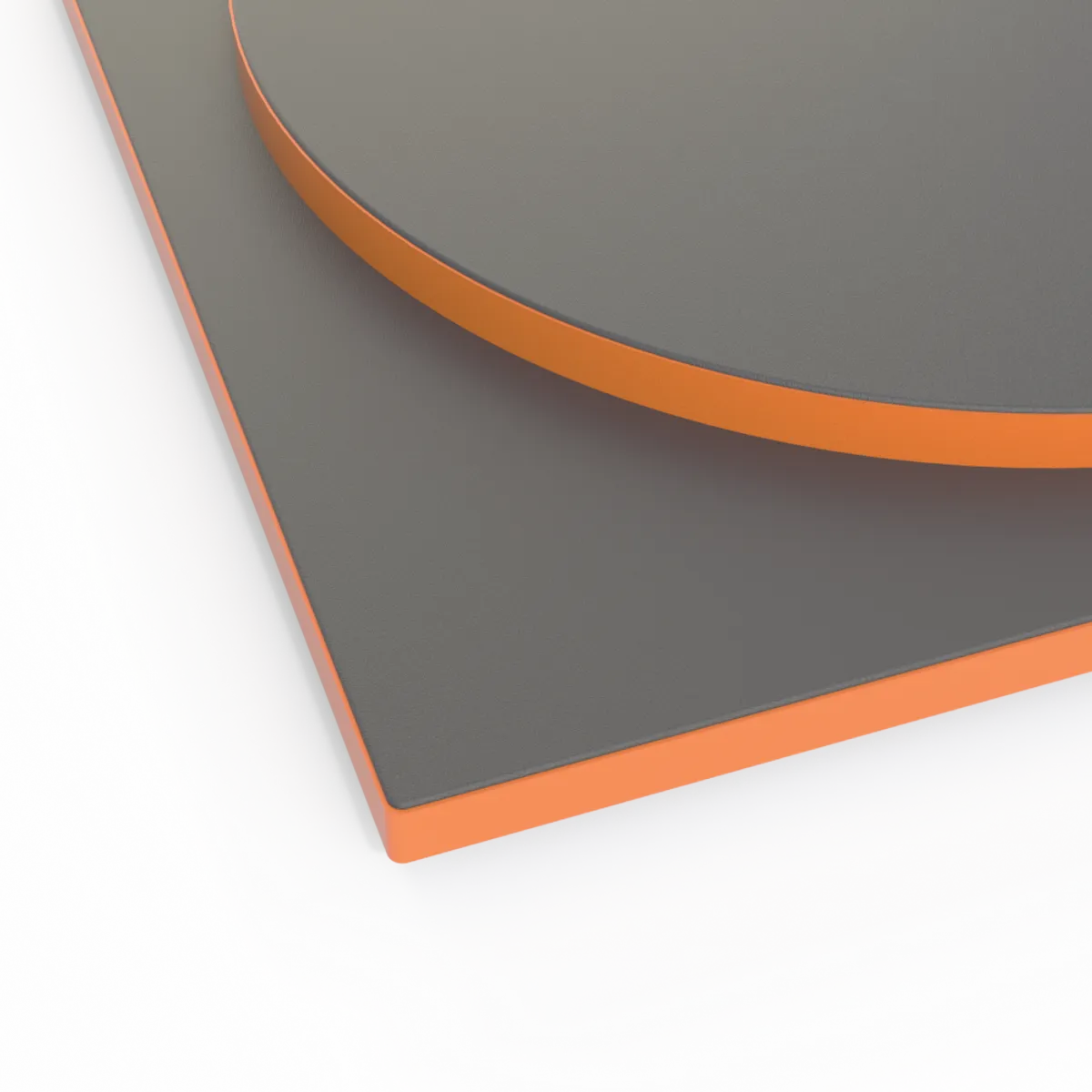

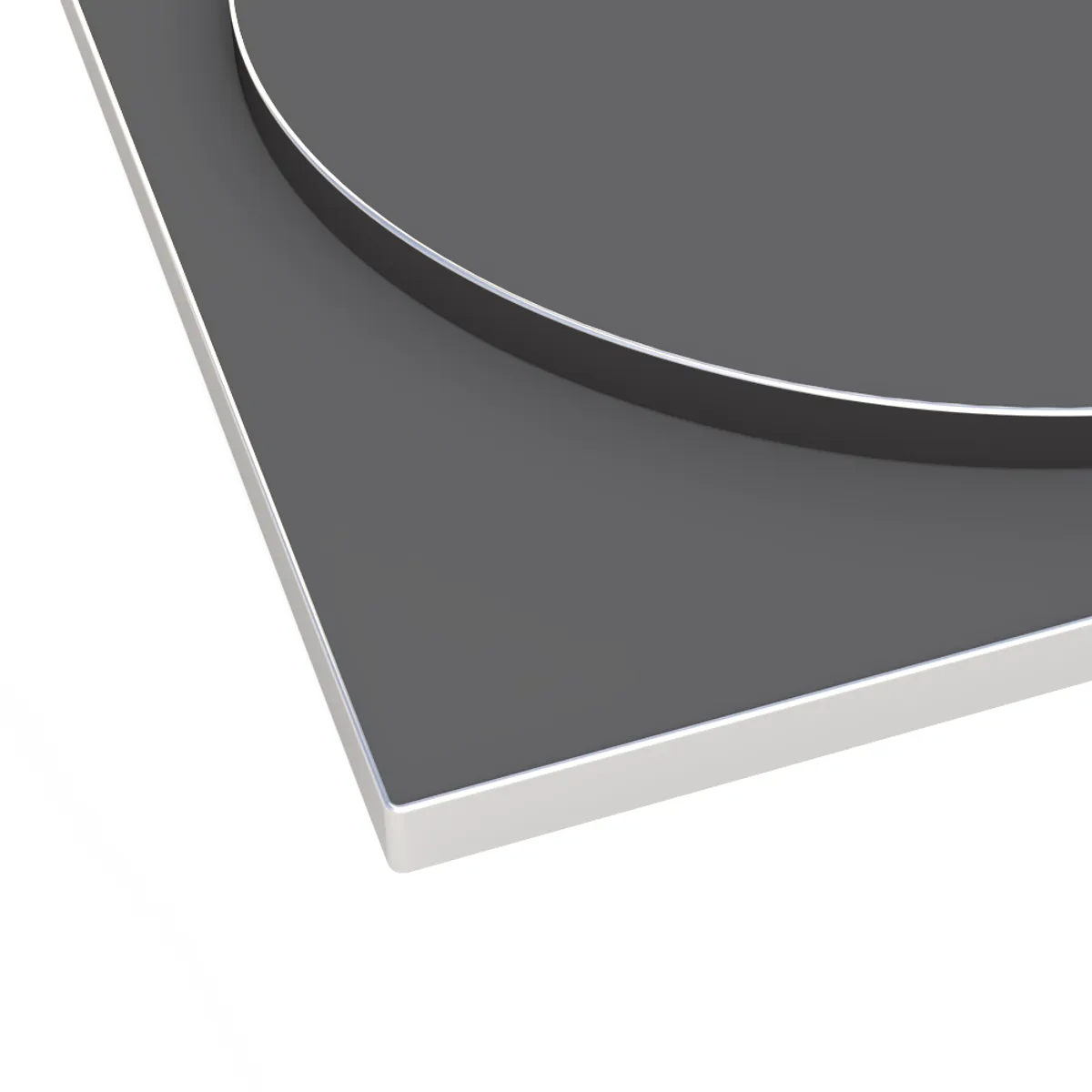

Metal Edge

Metal edging is available in a range of metals such as brass, copper and chrome. As metal naturally expands and contracts, pulling away from the surface of the edge, it’s important that we attach metal edging correctly.

For solid wood (and stone) table tops, screws must be used, either on the side or underneath the top, depending on the edge profile.

Download Our Table Top Care Guide

Do you have a question?

You can request a call with one of our creative furniture experts today.

Let us know when is the best time and method to contact you and we will get in touch to discuss your query or project.

Looking for a particular product?

Inside inspiration

Join us on Instagram to follow our recent projects.

Inside Out Contracts

Building 16, 42 Creek Road, London SE8 3FN

Sales: +44(0)20 8305 3130

Production: +44(0)20 8305 3136

Design: +44(0)20 8305 3139

Company No. 02841010

VAT No. 752 0164 61